Summer Heat Test: What Happens to Structures That Aren’t Precast?

- Dukane Precast

- Jul 30, 2025

- 2 min read

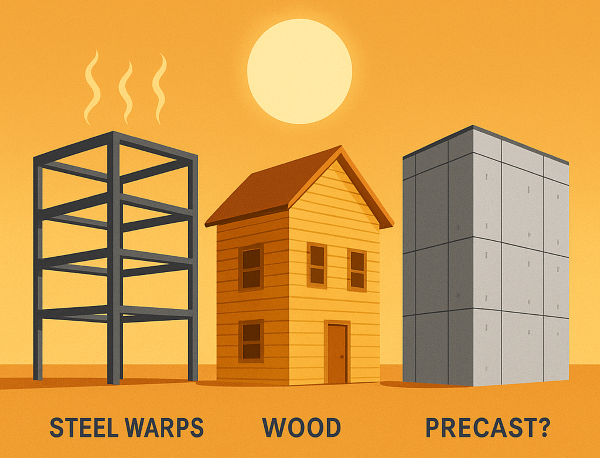

As summer temperatures rise, so does the pressure on the materials used in our buildings and infrastructure. Extreme heat can push conventional materials like steel, wood, and CMU to their breaking points—literally. Warping, swelling, cracking, and increased cooling demands can lead to costly maintenance, safety concerns, and inefficiencies.

So what happens when the heat is on? Let’s break down how materials respond—and why precast concrete stands above the rest.

The Heat Problem in Construction

When exposed to high temperatures, different building materials react in problematic ways:

Steel expands and warps, potentially compromising structural alignment and causing long-term fatigue.

Wood swells, twists, or shrinks depending on humidity levels, often leading to misaligned framing or cladding gaps.

CMU (concrete masonry units) can crack due to uneven expansion or moisture entrapment in hot conditions.

These reactions are more than cosmetic—they can affect a building’s structural integrity, increase cooling costs, and shorten the lifespan of key components.

The Precast Advantage in Summer Heat

Unlike traditional materials, precast concrete is engineered to handle extreme temperatures with minimal impact. Here’s why it performs so well in hot weather:

Thermal Mass That Works With Nature

Precast concrete has high thermal mass, which means it absorbs heat slowly and releases it gradually. This delays internal temperature spikes during the day and reduces cooling demands—especially important in climates with high diurnal swings.

Benefit: Reduced HVAC loads, more consistent interior temperatures, and greater occupant comfort.

Dimensional Stability Under Pressure

Precast doesn’t warp, swell, or shrink with heat exposure. Its dimensional integrity makes it ideal for structural walls, facades, and enclosures that need to maintain tight tolerances over decades.

Benefit: Minimal maintenance, fewer performance-related callbacks, and better compatibility with other materials over time.

Fire and Heat Resistance

Unlike combustible or thermally vulnerable materials, precast retains its structural strength in high temperatures and offers superior fire resistance ratings.

Benefit: Safer structures, especially in wildland-urban interface zones and industrial applications.

Better in Heat = Better ROI

Choosing precast doesn’t just improve performance—it enhances your bottom line:

Energy Efficiency: Reduced cooling costs in summer.

Lower Maintenance: No warping, repainting, or corrective work due to thermal movement.

Long-Term Value: Precast holds up over decades without degradation from seasonal extremes.

Whether you’re building a school in the Southwest, a data center in the Southeast, or an industrial facility in a heat-prone zone—precast concrete is designed to handle the heat without compromise.

Build Smarter in Hot Climates

Materials matter—especially when the environment turns hostile. As climate patterns shift and heatwaves become more frequent, resilient construction isn’t a luxury—it’s a necessity.

Want to see how precast performs under pressure? We’ll show you real-world examples, performance data, and the design flexibility that comes with building precast.

Comments